For anyone who has had the opportunity to take a look at the Galaxy S6 Edge, you’ll realise that a lot of engineering and intricate manufacturing has taken place in order to process the very classy edge and aluminium body featured on the new flagship device.

Now, just a day or so after the official announcement of both the Galaxy S6 and also the Edge, Samsung has explained in detail how they go about manufacturing such a product for the masses.

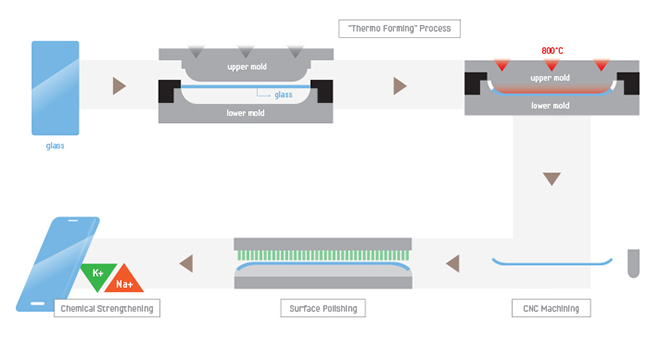

Both devices feature glass on the front and back, with the S6 edge having an attractive curved glass on the front, both phones feature an aluminium frame that goes around and inside the phones. The glass on the S6 Edge is made using a process called 3D thermoforming; the glass is pressed between two moulds after heating it to 800 degree Celsius, this gives the phone it’s curved edges on either side and it’s finally polished to give it the desired finish. On the back on the smartphones, Samsung has used nano-thin multi-coating process, which gives the back the particular appearance that seems to give the impression that the colour gently changes depending upon the angle you look at it.

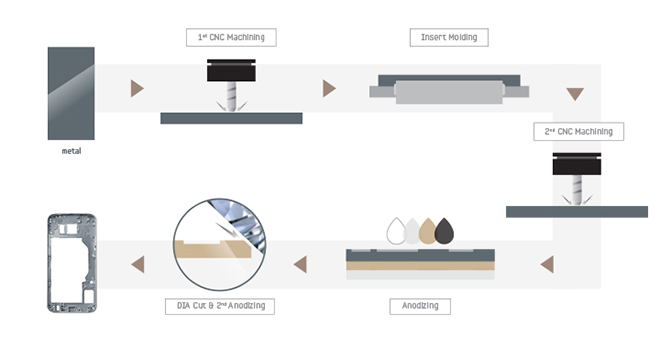

Moving on to the metal manufacturing process, Samsung use a high-strength 6013 aluminium alloy instead of the more common 6063 aluminium alloy. 6013 is commonly used as an aerospace alloy designed to be much stronger, it’s primarily used in aircrafts fuselage panels but also is seen on yachts and even high-end mountain bikes. Compared to the more common 6063 aluminium alloy, it’s around 1.5x stronger and 1.2x scratch resistant than 6063 aluminium alloy. During the manufacturing process, the metal goes through multiple processes, starting by CNC machining the aluminium block, anodizing, and then polished around the edges with a diamond tipped tool to give it the polished chamfered edges. After this has been complete, the antenna becomes an integral part of the body of the handset as it’s welded to the metal frame using ultrasonic welding.

After manufacturing has been complete, Samsung claim that the devices go through a rigorous testing process that includes dropping and bending the handset to see how the materials cope. Hopefully when released, this extensive stress testing should become evident, as I’m sure a curved screen won’t be cheap to repair should it be smashed.